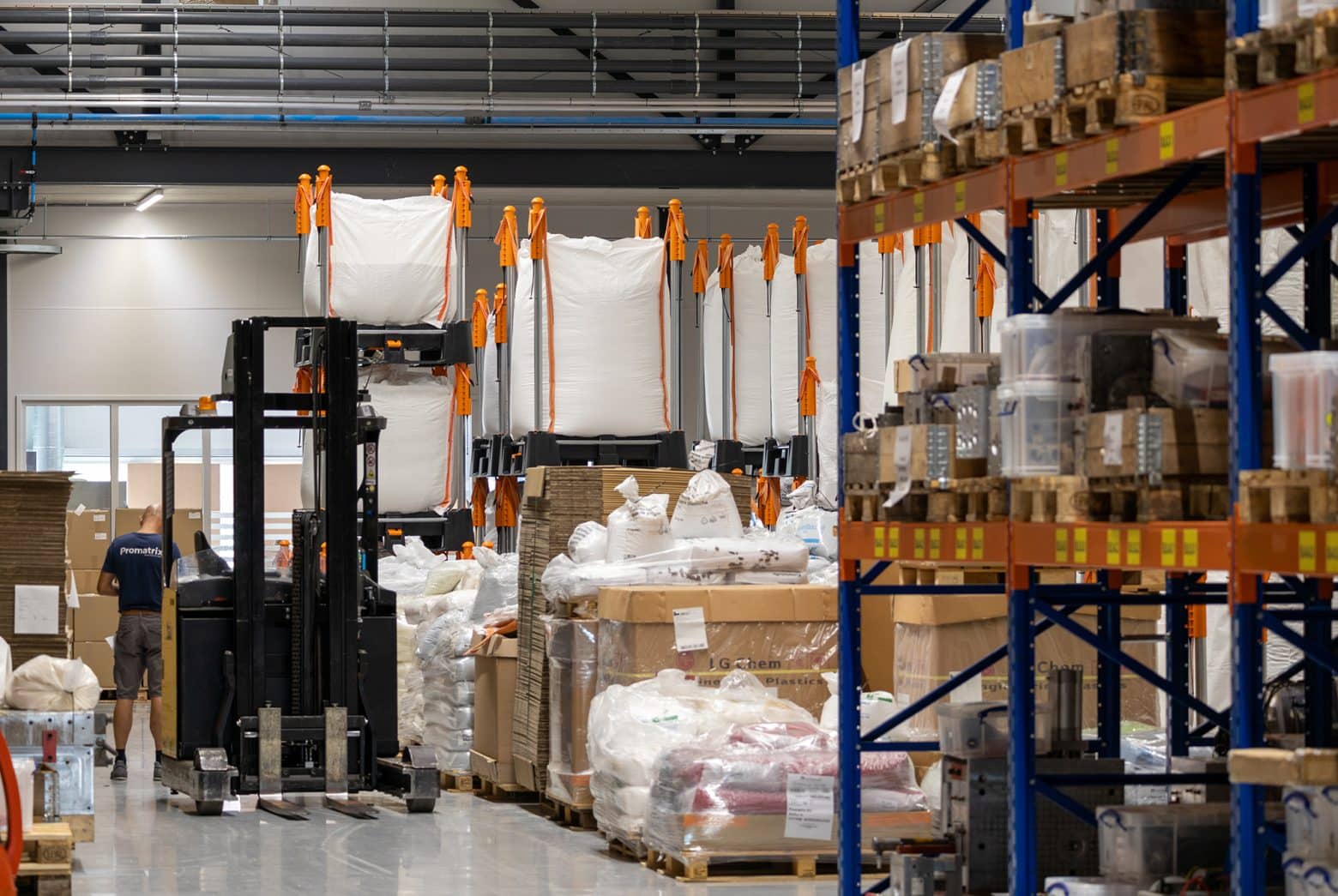

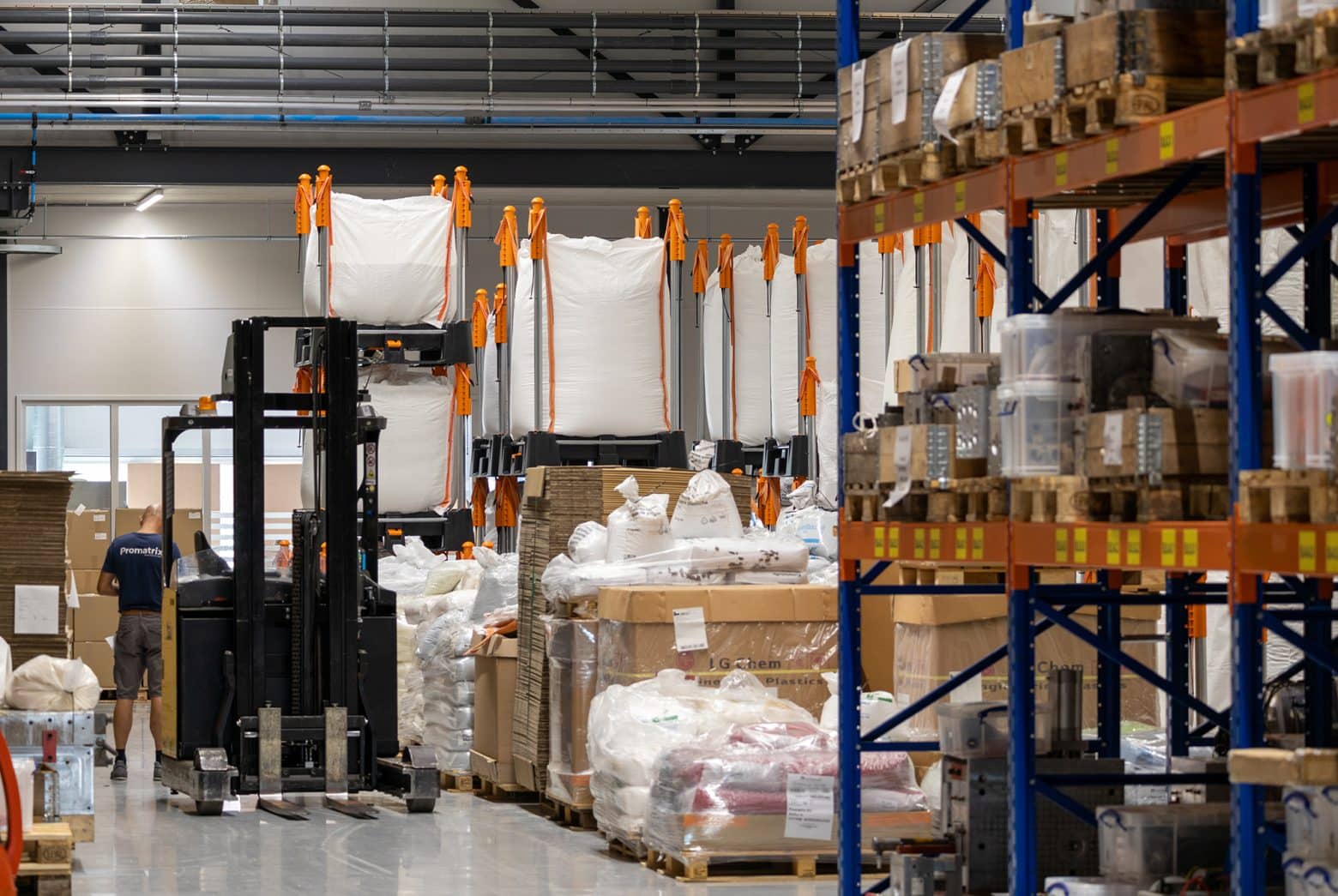

In industrial sectors that use large volumes of bulk materials, it is important to be able to store these in an efficient way. In addition, it is helpful if bulk material can be transported to production. Big bags, also known as FIBCs (Flexible Intermediate Bulk Containers), are a widely used packaging solution for these materials. That is because they are cheap, durable, and easy to use. The use of a specialist big bag handling system like the Indus Neva offers many advantages over traditional pallet racking. Especially in terms of use of space, safety, and supplementary functions in production. In this article, we discuss the advantages of the unique big bag system over traditional pallet racking.

The flexibility of use is an important advantage of the bag handling system over a rack in the storage facility. The Indus Neva system can be set up easily in the event of an increase in stock requirements or dismantled if the need decreases again. This represents a 60% decrease in the use of space with normal use of a big bag of 100x100x100 cm. This makes it possible to adapt storage space to meet changing demands, thereby avoiding unnecessary use of space and costs. Pallet racks are often anchored in the ground and require more time and effort to change, which can hamper operational flexibility.

The big bag handling system offers a high level of safety for both the transporting and stacking of big bags. The tub-shaped deck and vertical poles keep the big bag in place and stable, even when transported with a forklift truck or when stacked 4 layers high. This reduces the risk of accidents, product damage, and injury to employees. The big bag handling system offers a superior safety solution compared to pallet racking, which poses a risk of instability and the big bags falling over.

Another advantage of the big bag handling system is the function it has in production. Whereas a loose big bag on a wooden pallet has to be removed from a pallet rack and then hung in a hanging frame in production, the big bag handling system can be used for both storage and production. The system enables efficient dosed discharge of big bags by placing the deck on a container or above a processing line. This enables a seamless transition between storage and production, which optimises the workflow and improves production efficiency.

Indus strives to accelerate the transformation to sustainable, accessible and safe handling of solids in the industry. Do you need advice on the appropriate use of big bags in your storage or production facility? Don’t hesitate to contact us.

In the world of industrial packaging and logistics, big bags or FIBCs have long been an excellent choice for transporting and storing bulk goods. They offer significant cost advantages compared to traditional packaging materials like 25 kg bags and octabins.

Processing bulk goods is a challenge. Indus makes a completely new way of emptying big bags possible with our unloading stations.

Looking for a simple way to unload your stored bulk goods in doses? Get to know the dosing unloading station.

Pallets form a large waste stream within logistics companies. Reducing the wood flow for these pallets is not only interesting because of sustainability but will soon become mandatory under European legislation.

Indus will be present at SOLIDS in Dortmund 9-10 October 2024, to present the most innovative solution for storing, processing and transporting materials from big bags.

Stack your bulk goods in big bags / FIBCs safely with our Indus Neva.