Enza Zaden: a notable business in the world of vegetable seed breeding. The Dutch company from Enkhuizen introduces many new vegetable varieties every year. Seeds are developed all over the world: from the Netherlands to Australia, on almost all continents. The production and sales of seeds, including many varieties of lettuces, occurs worldwide as well. For over six years, the Neva system from Indus Integrated Bulk Logistics has been playing an important role in the transport and packaging of these lettuce seeds.

The profit that Enza Zaden achieves with the use of the Neva:

Would you like to know what we can do for you? Contact us directly or request a demo!

Team leader of processing, Pieter Pereboom, explains: ,,The lettuce customers buy at the grocery store, have been on quite a journey in order to get there. Enza Zaden breeds seeds in several climate zones. Fruit crops such as peppers, cucumbers, pumpkins and tomatoes are grown in greenhouses, other vegetable crops such as lettuces are grown in fields. Part of the production takes place here in the Netherlands, but we also produce in California, Australia and Malaysia, among other countries.The most vegetable seeds Enza Zaden breeds and produces, are fairly easy to prepare for sale. ,,The seeds are firm and strong enough to be sown directly by the growers who purchase our seeds. The exception to this is our lettuce and endive seeds. These seeds are so small and light-weighed; they easily blow away when sown. To prevent this from happening, lettuce seeds are being pelleted. The pelleting process means the seed is covered with a small layer of clay, making it easier to accurately sow them.’’

Most of the seeds that Enza breeds and produces are fairly easy to prepare for sale. “These seeds are strong enough to be sown directly by the gardeners who purchase from us. The exception to this is our lettuce and endive seeds. These are so small and light that they blow away when they are sown. To prevent this from happening, lettuce seeds are pelleted. This is a process in which the seed is covered with a layer of clay. This makes it easier and more accurate to sow.”

Because pelleted seeds are vulnerable due to their extra layer, Enza Zaden prioritizes a steady and smooth (internal) transport. Pereboom: ,,We used to receive the pelleted seeds in cases of twenty kilos each. Our packaging system consists of a weighing machine accessible through stairs, which meant our employees had to walk up these stairs several times a day to empty the cases. We have been following this packaging process for years, until Incotec, the company that pellets our seeds, told us about the big bag handling system of Indus Bulk Logistics.”

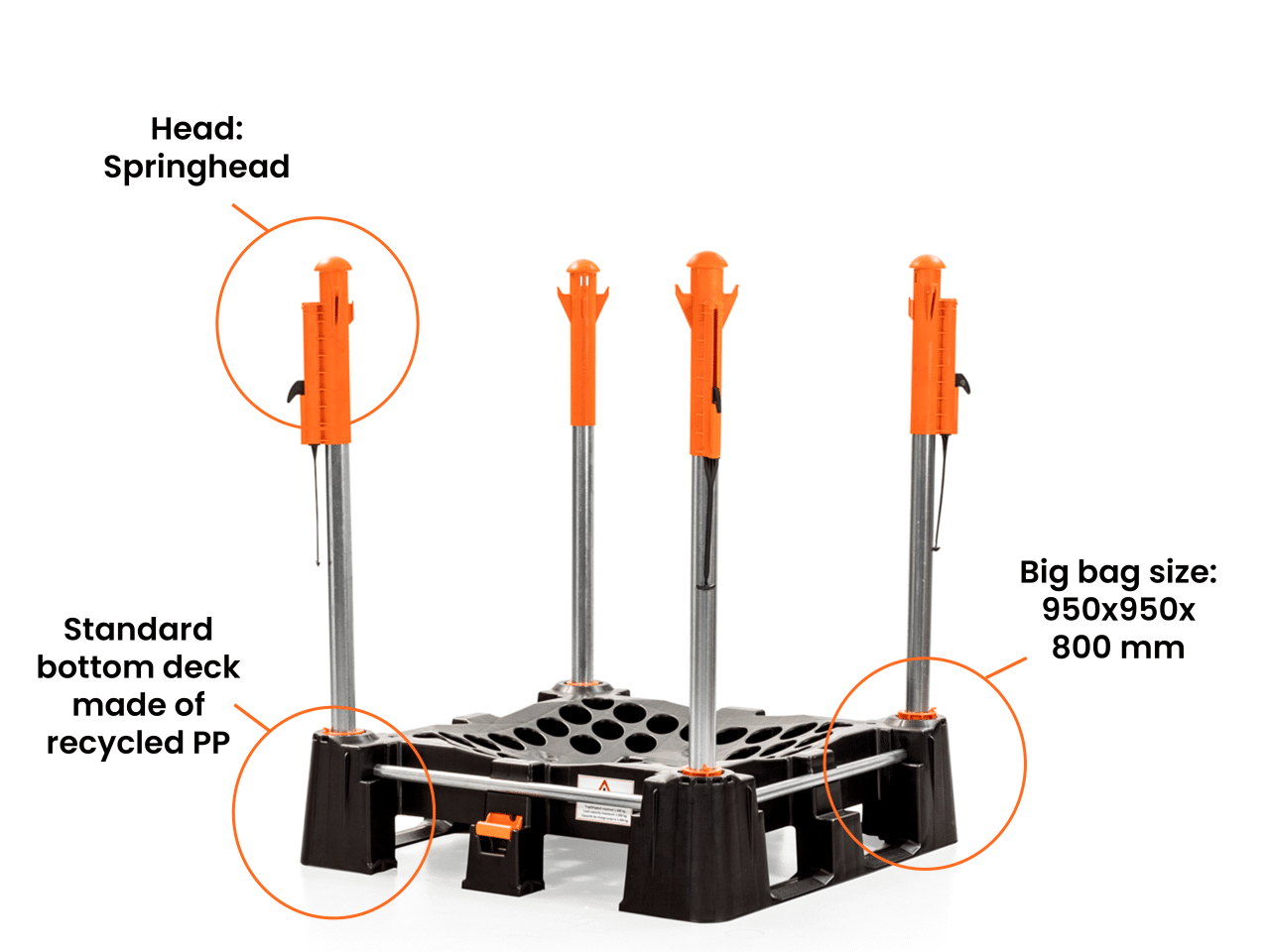

Along with some colleagues, Pereboom visited Incotec to observe the use of the Neva handling system at Incotec. The team, as well as the management of Enza Zaden, were quickly convinced. The time savings and the improvement of safety during the packaging process were among the decisive factors. ,,After purchasing various Neva’s, we built a special frame above the weighing machines making a Neva of 120x120cm fit exactly in this frame. From that moment on, more than twenty times the volume of lettuce seeds could be stored and transported in one big bag, compared to one case before.

By using the slide at the bottom of the Neva, the discharge spout of the big bag in the lower deck can be opened and closed. Due to the pallet construction, a Neva can easily be transported with a forklift. Additionally, several Neva’s can be stacked on top of each other or placed in racks: going up and down the stairs with heavy cases is now a thing of the past.”

With the arrival of Neva, the time was right to create suitable big bags for pelleted lettuce seeds. A local sailmaker was willing to fabricate special big bags made to measure, entirety waterproof and antistatic. ,,We visited the sailmaker and brought a Neva along with us, to show them how we would use the big bags. When choosing the material for the big bags, the importance of protecting the pelleted seeds was take into extra consideration’’, says Pereboom.

In addition to the advantages mentioned above, the savings in space when transporting seeds to and from Incotec were a large part of deciding to purchase Neva’s. ,,Incotec gave me some great advice at the time: shorten the four tubes of the Neva in such a way that it is possible to stack two on top of each other in a truck. Incotec now only needs to fill a single unit, instead of multiple cases: a huge advantage for them as well as for us.”

After six years, hundreds of Neva’s can be found at Enza Zaden. ,,They are used extensively and all year around; fifteen times a day in our packaging process alone. There was a short period of adjustment for my team when we introduced the new system, but they were quickly convinced and would not want to go back to the old process. The use of the Neva system increases safety and convenience, and it saves time: it has proven itself excellently and has been more than worth the investment.’’

By using the Neva, the machines from Promatrix no longer stop unintentionally.

From harvest to bread; How the Indus Neva makes processes more efficient, cleaner and easier.

Rijk Zwaan continuously strives for efficiency improvements. This led to the purchase of the Indus Neva for the packaging department.

As a producer of over five million plastic garden furniture sets per year, Jardin processes countless plastic granules on an annual basis.

Getting ready for peak production and optimizing the storage capacity by using the Nevas.

“The Neva system keeps our production lines, and therefore our products, clean”